Reactor Feed: Up to 6 gases and 2 liquids can be used in the standard

configuration of the μBenchCAT. Each gas train incorporates a filter, electronic mass

flow controller (MFC), check valve, and positive shut-off valve. The range and gas

calibration of each MFC is specified by the customer. Liquids are delivered using high

precision HPLC pumps.

Condenser: A tube-in-tube condenser is located outside the oven at the

outlet of the reactor. A thermocouple is used to monitor the coolant return.

Gas/Liquid Separator: The gas/liquid separator is found downstream of

the condenser. Two level switches (high and low) activate an automatic valve and serve

to maintain level control.

Pressure Control: Exit pressure is measured with a separate pressure

transducer and the pressure is controlled using an automatic tapered needle valve.

Product Sampling Valve: An optional product sampling valve can be used

to route an effluent sample to an external analytical device.

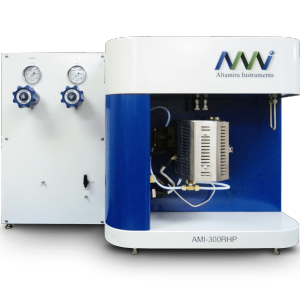

Specific

surface area analyzer

Specific

surface area analyzer

Specific surface area analyzer

Specific surface area analyzer

TEL: +86 010 63326036

TEL: +86 010 63326036

ENAIL:sales@jwgb.net

ENAIL:sales@jwgb.net

TEL: +86 010 63326024

TEL: +86 010 63326024

EMAIL:sales@jwgb.net

EMAIL:sales@jwgb.net

TEL: +86 010 63326024

TEL: +86 010 63326024

EMAIL:sales@jwgb.net

EMAIL:sales@jwgb.net