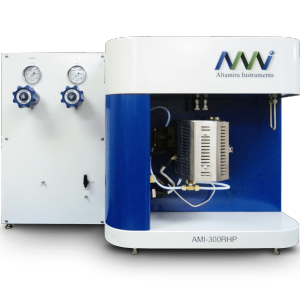

Based on our successful AMI-300 instrument, the AMI-300Lite allows for rapid chemisorption studies in a compact, affordable package. The AMI-300Lite was designed specifically for the price-conscious customers with applications that are more routine or less demanding. As always, full automation and powerful data-handling software assure data accuracy and improve laboratory efficiency.

About us

Beijing JWGB Instrument Co., Ltd.

sales@jwgb.net

Copyright 2004–2024 JWGB.NET

Specific

surface area analyzer

Specific

surface area analyzer

Specific surface area analyzer

Specific surface area analyzer

TEL: +86 010 63326036

TEL: +86 010 63326036

ENAIL:sales@jwgb.net

ENAIL:sales@jwgb.net

TEL: +86 010 63326024

TEL: +86 010 63326024

EMAIL:sales@jwgb.net

EMAIL:sales@jwgb.net

TEL: +86 010 63326024

TEL: +86 010 63326024

EMAIL:sales@jwgb.net

EMAIL:sales@jwgb.net